Vishnu Garden, Delhi

- GST NO. : 07BPBPS1199P2Z4

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler, Trader, Distributor |

| Material | Cast Iron |

| Condition | New |

| Capacity | 50-100kg/h |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

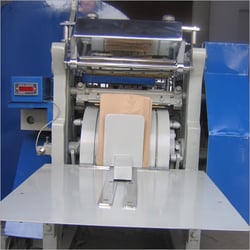

Paper Bag Making Machine is Designed to Manufacture Flat and Satchel Paper Bags from Kraft Paper, Greaseproof, White Paper and Poster Paper Etc. in Different Size for Packing Confectionery, Food Stuff, Ready-made Garments, Tobacco, Tea Powder Grocery, Dry Cleaners Etc.

Our Paper Bag Making Machines are successfully working Overseas in Palestine, Lebanon, Saudi Arabia, Uganda, Ireland, Egypt, Morroco, Kuwait, Chile Etc.

Paper Bag Making Machine is Made of rigid and Robust Construction to Avoid Vibration. All Paper are Arranged in Most Accessible Way Thus Making Operation and Adjustment Very Simple and Quick So That Even an Unskilled Labour Can Easily Operate the Machine Successfully. The Change of Size is Very Easy And Can be Done in Few Minutes Time. The Machine is Supplied with One Size Plate and One Size Gears to Manufacture One Size of Paper Bag. Different Size Plates & Size Gear For Flat And Stachel Bags Are Available At Extra Cost. Mill Reels Upto 34” Dia and 34” Width Can be Accommodated of the Machine. The Width of the Paper Reel to be Fed on the Machine Can be Calculated as Under.

Flat Bags Twice the Bag Width Plus 2 CM for Centre Seam.

Satchel Bags Twice the Bags Width Plus 4 Time Depth of the Gusset Plus 2 CM For Centre Seam.

Bag Formation

The Required Size of the Bag us Obtained by Fixing The Exact Size Plate For Flat or Satchel to the Size Plate Holder And the Length to the Tube Is Obtained by Changing the Size Gear Wheel, Each Tooth of Which , Represents One Centimeter in Length, The Tube After Being Cut by the Beater Into Exact Size As Per the Size Gear is Carried Forward By Means Of Conveyor Rollers to the Delivery Cylinder the Delivery Cylinder As the Bottom Fold Is Made is the Bag it is Pasted and the Bag is Carried by the Folding Cylinder to the Delivery Table Where it is Released and Delivered in a Vertical Stack.

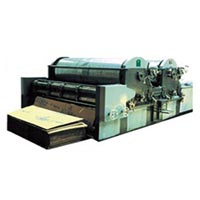

Printing Attachment

Our Two or Four Colour Flexo Printer Can Be Coupled With the Paper Bag Making Machine.

Specifications

|

Model |

Large |

Medium |

Standard |

Baby |

|

Max. Size of Bag |

42cm x 60 cm |

28cm x 50cm |

26cm x 36 cm |

15cm x 22 cm |

|

Min.Size of Bag |

12cm x 18 cm |

12cm x 18 cm |

5 cm x 10 cm |

5 cm x 10 cm |

|

Capacity per 8Hr. |

50-60,000 bags |

60-70,000 bags |

70-80,000 bags |

80-90,000 bags |

|

Flexo Printing |

1,2,3,4 Colours |

1,2,3,4 Colours |

1,2,3,4 Colours |

1,2,3,4 Colours |

Looking for "Paper Bag Making Machine" ?

Explore More Products